NO.12 เครื่องเชื่อม 2 หัว (SHZ2-120×3500)

Two Head Welding Machine

Features:

- PLC controls the welding action / program, high reliability

- Machine heads can work separately or jointly

- Free angle welding on right machine head

- Parameters can be set to meet various profiles’ processing requirements

- High welding precision

- Imported temperature controller and other main electric components.

- Good welding corner appearance

Parameter:

- Operation Air Pressure: 0.5~0.8 (MPa)

- Air Consumption: 40(L/min)

- Input Voltage: 220V 50Hz

- Input Power: 2.5 (kw)

- Welding Height: 20~120 (mm)

- Welding Width: 120 (mm)

- Welding Range: 400~3500 (mm)

- Overall Dimension: 4400×1000×1700(mm)

- Machine Weight: 850(kg)

- Published in mechine

NO.11 เครื่องบากหัวเสาเกี่ยว (SXF-18×20)

Cap-seal Milling Machine

Function:

Milling various cap-seals of sliding windows.

Features:

- Quick and convenient cutter change for short production cycle.

- Adjustable profile leading plate, only need to set the locating width when process different profiles.

Parameter:

- Input Voltage:220V 50Hz

- Input Power:750W

- Main-Shaft Revolution:2800r/min

- Cutter Diameter:φ130mm

- Milling Range:18mm×20mm

- Overall Dimension:530mm×530mm×1100mm

- Weight:100kg

- Published in mechine

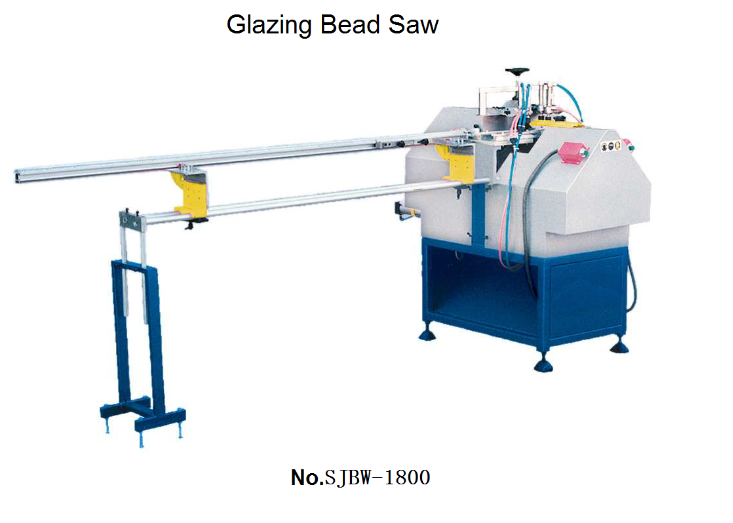

NO.10 เครื่องตัดคิ้วล็อคกระจก (SJBW-1800)

Glazing Bead Saw

Function:

For 45° glazing bead cutting.

Features:

- Special measurement scale, easy to operate.

- One time two pieces of glass batten cutting.

- Design with adjustable mould, change the profile but not change the mould, avoid reinvestment and reduce the production preparation period.

- Adjustable positioning plate design with fine tuning device so that made the interior corner sealed after assembling the bead.

Parameter:

- Air Pressure: 0.5MPa~0.8MPa

- Air Consumption: 20L/min

- Input Voltage: 380V 50Hz

- Input Power: 1.1KW

- Spindle Rotary Speed:2800r/min

- Cutting Height: 33mm

- Cutting Width: 100mm

- Cutting Length: 320mm~1800mm

- Overall Dimension: 2500mm×1380mm×1300mm

- Weight:250kg

- Published in mechine

NO.9 เครื่องทำความสะอาดมุมด้านนอก (SXW)

External Corner Cleaner

Features:

For external corner cleaning

Adopted imported air grinder, along with air source disposer

- Pneumatic drive

- Precise positioning, compact structure and easy operation

Parameter:

- Air Pressure: 0.5~0.8(MPa)

- Air Consumption: 15(L/min)

- Overall Dimension: 80×58×46(mm)

- Weight: 1.15(kg)

- Published in mechine

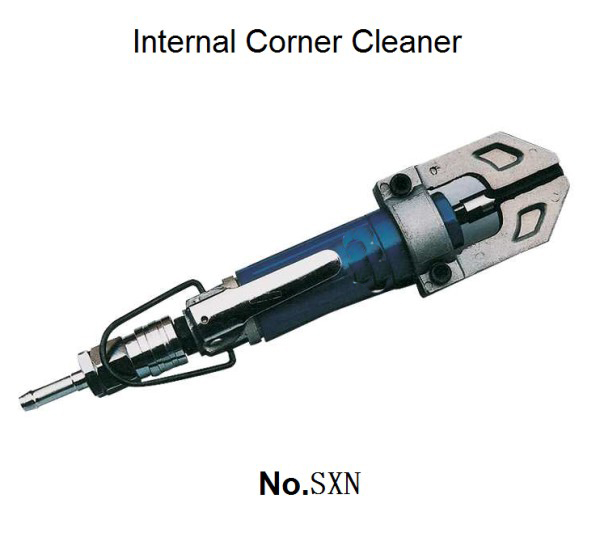

NO.8 เครื่องทำความสะอาดมุมด้านใน (SXN)

Internal Conner Cleaner

★Function

For internal corner cleaning

★Features

Pneumatic drive, adopt imported air grinder, along with filter.

Precise positioning, compact structure and easy operation.

- Published in mechine

NO.7 เครื่องทำความสะอาดรอยเชื่อมแนวนอน (SQ-120)

Portable Corner Cleaning Machine

Features:

For ┌ shaped or ┬ shaped corner cleaning

1. Pneumatic drive

2. Precise positioning, compact structure and easy operation

Parameter:

- Air Pressure: 0.5~0.8(MPa)

- Air Consumption: 25(L/min)

- Profile Width: 30~120(mm)

- Overall Dimension: 550×160×190(mm)

- Weight: 4.8(kg)

- Published in mechine

NO.6 เครื่องทำความสะอาดมุม (CNCSQJ-CNC-120)

Corner Cleaning Machine CNC

Function:

For profile welding seam cleaning.

Features:

- Two axis computer control system.

- Imported servo motor drive system, computer control system, solenoid valve, air source disposer and so on, ensure reliable performance and long using life.

- Horizontal inward clamping system ensures the precision of the corner cleaning.

- Clean outside vertical surface, up/bottom welding seam and seal rubber groove part, and also can process the lock slot of lift sash for American profile once time.

- Can store many programs for various profile processing.

Circular interpolation and line interpolation function to ensure the good cleaning result. - Can customize different knives according to different profile section for meeting different clean requirement.

Parameter:

- Air Pressure: 0.5MPa~0.8MPa

- Air Consumption: 80L/min

- Input Voltage: 380V 50Hz

- Input Power: 1.4KW

- Main Cutter Revolution:2880r/min

- Profile Height:30mm~120mm

- Profile Width:20mm~120mm

- Overall Dimension:1570mm×2670mm×2070mm

- Weight:500kg

- Published in mechine

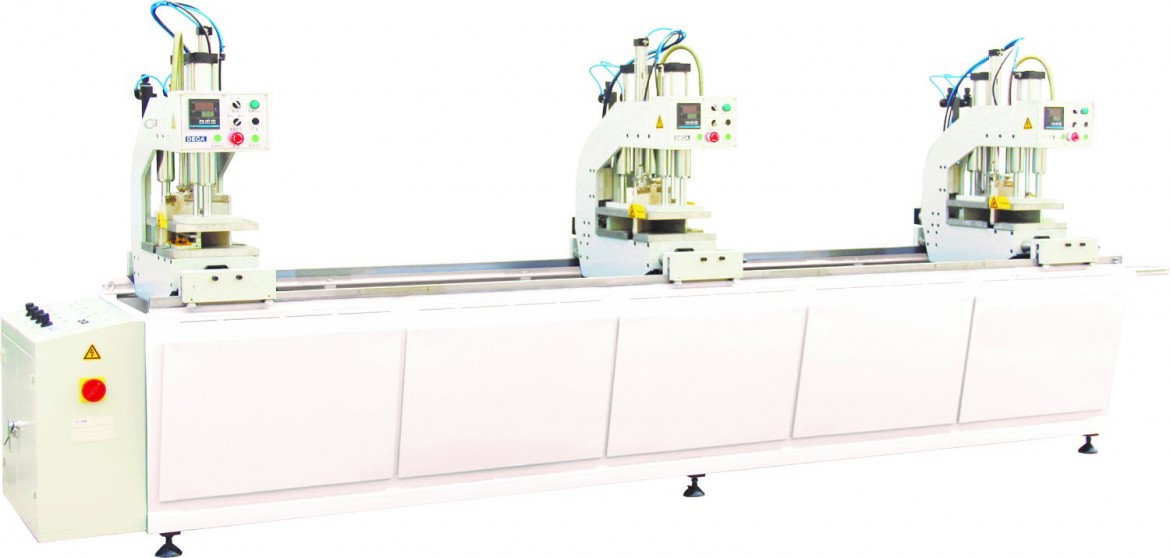

NO.5 เครื่องเชื่อม 3 หัว (SHZ4GC-120×3500)

Three Head Welding Machine

Function:

Used for corner and mullion welding of PVC profile.

Features:

- Four head can work separately or corporately, flexible combination.

- PLC controls the welding action / program, high reliability.

- Free angle welding of right machine head.

- Parameters can be set to meet various profiles processing requirements.

- High welding precision.

- Adopt high quality electrical and pneumatically components with high reliability.

- Good welding corner appearance.

Parameter:

- Air Pressure: 0.6MPa~0.8MPa

- Air Consumption: 60L/min

- Input Voltage: 220V 50Hz

- Input Power: 3.5KW

- Welding Height: 20mm~120mm

- Welding Width: 120mm

- Welding Range: 400mm×400mm~3500mm×3500mm

- Overall Dimension: 4400mm×1000mm×1700mm

- Weight:1080kg

- Published in mechine

NO.4 เครื่องเจาะรูกุญแจ/เจาะรูมือจับ SZSB-100

Lock Hole Machine

Function:

Milling all kinds of lock holes

Features :

- Formed by three-hole drill part (horizontal direction) and copy milling part (vertical direction)

the height of three-hole drilling can be adjusted easily - three-hole drill designed behind and operated easily.adopt vertical axis to ensure the parallel precision of the three-hole drill adopt hydro-pneumatic actuator cylinder feeding to save labor.

- easy adjustment of the processing position

Parameter:

- Operation Air Pressure: 0.5~0.8(MPa)

- Air Consumption: 20L/min

- Input Voltage: 380 50Hz

- Main-Shaft Revolution: 11200/910(r/min)

- Input Power: 1.1 (kW)),0.75(kW)

- Three-hole Cutter Diameter: Φ12,φ10(mm)

- Copy cutter diameter: Φ5, Φ8

- Copy Milling Range: 90×290(mm)

- Overall Dimension: 3150 x 1020 x 1600 mm

- Machine Weight: 400(kg)

- Published in mechine

NO.3 เครื่องเจาะรูระบายน้ำ LXCA-60

Auto Water Slot Milling Machine (Three Axis)

Function:

Milling all kinds of water slots and air pressure balance grooves.

Features:

- Full design with high rigidity, processing beautiful water slot, high appearance quality.

- Automatic cutter changer on the under head, one time clamp, two end water slots processing.

- High efficiency, suitable for mass production.

- Special feeding system, need no special maintenance, high milling quality.

- Convenient adjustment for the cutter location to meet different kinds of profiles.

- Water slot milling length adjustable within 100mm, wide adaptability.

- Adopt linear bearing motion to ensure the processing precision.

Parameter:

- Air Pressure:0.5~0.8(MPa)

- Air Consumption: 30(L/min)

- Input Voltage:220V 50Hz

- Main-shaft Revolution:25000(r/min)

- Input Power: 1.14(kW)

- Cutter Diameter:φ5 φ8 (mm)

- Slot Length:0~100(mm)

- Overall Dimension:1200×1200×1800(mm)

- Weight:300(kg)

- Published in mechine

- 1

- 2